By Sabrina Fatma Ahmad and Tarin Fatema

The evolution of our apparel industry in Bangladesh is our very own Cinderella story. From its humble beginnings as small businesses cropping up in a new nation, to its rise to the status of clothes-maker for the world, from its dark past muddied by exploitation of both human and natural resources, to its rapid turnaround and push for sustainability, it has continued to grow and develop and defy expectations.

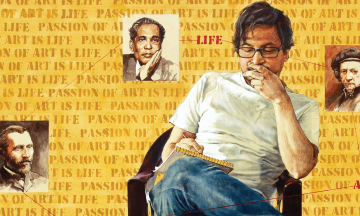

Since the beginning of his career in this field in 1982, few have enjoyed the vantage point of the inner workings of the industry that Faruque Hassan, Managing Director of Giant Group, has. And as the President of the Bangladesh Garments Manufacturers and Exporters Association (BGMEA), he is poised to lead the sector into a new paradigm. Ahead of the Made in Bangladesh Week, MWB catches up with the man of the moment for a conversation about the future of fashion.

The drive to the new BGMEA complex in Uttara feels like a metaphor. The urban tangles of buildings slough off like old skin as concrete roads give way to bumpy dirt paths fringed with autumn’s fluffiest kans grass, sparkling wetlands visible beyond. The bones of a half-completed MRT bridge fly overhead, punctuated by what is shaping up to be a beautiful station. It’s like watching Bangladesh starting to crawl from the messy, complicated business of development to a more sustainable future.

The 15-storey behemoth that is the BGMEA complex is an imposing structure, slowly coming to life. Sleek surfaces of metal and stone peek from behind the packaging, in tasteful warm neutrals. A swift elevator ride brings us to the lushly appointed offices of the BGMEA President, where our cover shoot is underway. Standing in the eye of the storm, getting a quick wardrobe tweak while simultaneously firing off instructions pertaining to upcoming events and activations, is Faruque Hassan. We dive right into business.

This is an impressive office! Do tell us what we can look forward to, both in terms of this brand-new building, and your plans for the industry in general.

We have a lot of plans around the building as we aspire to make a symbol of our future industry. There will be a museum, photo gallery, auditorium, expo zone, child care center, health center, and a state-of-the art innovation center. You may know that we have established a “Centre for Innovation, Efficiency and OSH.” Through this center, we will focus on newer avenues of enhancing our competitiveness through efficiency improvement and cost optimization. We will also work to facilitate automation, 3D designing, innovation, using best industrial engineering process and practices, enlighten on end-to-end digital manufacturing and inspire modular processes. We are also planning to establish a textile museum and exhibition center within BGMEA complex. To continue to innovate and make progress, we need to get people, particularly the new generation, involved, and we need to be doing everything to bring them in. We also applied for LEED certification by USGBC.

You have been in this industry for decades; you have seen it evolve and change in so many ways. Could you please briefly walk us through some of the most important highlights?

When the industry started out, there was a dream, but no organized, cohesive plan for how it should be established. The late Nurool Quader Khan sent 130 trainees to South Korea where they learned how to produce readymade garments, it was from this returning pool of workers that the industry took its first steps, the first factory. I remember Musa Shaheb (Akhter Mohammed Musa of Bond Garments) holding meetings in the drawing room of his house, talking about the need for a cohesive body for this industry. We had no industrial buildings until much, much later.

My predecessors, who laid down the foundation of this industry had to undergo many difficulties. I joined this sector in 1982, and witnessed a lot of these, and tried in my own capacity to carry it forward. When we started out, everything was imported, even the cardboard cartons used to pack the garments. At present, we’re producing everything – yarn, fabric, all accessories. We’re even doing design development, although there’s room for improvement here. Because, globally demand for non-cotton products has been rising. But we mostly export cotton-made apparel. Whereas 75% of the global textile and clothing consumption is non-cotton, only 25% of our exports are non-cotton. This means that we are not taking advantage of such a huge non-cotton market, while we have tremendous opportunities there.

We have made significant progress in the area of safety and social sustainability. From child labor elimination in 1995 till today, we are making many positive changes in the area of compliance, safety, and wellbeing of our workers. In the decade, we have made massive efforts in transforming the industry in terms of safety remediation of factories and creating a culture of safety at the workplace. To carry forward the progress that we have already made and to bring the Bangladesh RMG safety monitoring regimes under one umbrella, a national monitoring organization, the RMG Sustainability Council (RSC), has been established and working since 1st June 2020. The industrial building we now have, we tried to make it more environmentally friendly. We are trying to make it energy efficient. We have now 176 LEED certified green factories of which 57 are platinum.

We are trying to make sure that the next generation continues to take more sustainable approaches. We now have a fashion university – the BGMEA University of Fashion Technology (BUFT), which currently has 6,000 students enrolled. Recently, we got the permission to open the Chittagong University of Fashion Technology, work on which commences in January. So far, we have acted like tailors to the world, creating designs according to the patterns set by others. We’re on our way to setting the designs soon.

It has been a long, arduous journey, a lot of trial and error to bring about the changes you see today, but it has been an education. We have managed to become the world’s second largest apparel producer. We’re number 1 in terms of denim production and export, and the second largest exporter to the EU nations. There’s a lot to be proud of.

The next generation just entering now will take it even further. Many of them have studied formally in this field, both abroad and in local institutes. They are well-travelled, and have a good working knowledge about consumer demands, and can find new and meaningful ways to blend this knowledge with best practices and keep us moving forward. I want to draw your attention to our new logo, unveiled last June, which represents our current vision for the future.

We took the original single circle design, and, keeping the DNA of that design intact, we have tweaked it to create a dot matrix that speaks of our values.

The new logo

The nine dots logo is the matrix of BGMEA’s scope of work and influence. The dots are arranged in columns sequentially to portray BGMEA’s journey from micro to macro, from action to impact, and from local to global. It is an organic transformation. The connection continues when the nine dots are locked in rows. The first three dots emphasize ‘reach,’ the second three dots emphasize ‘transformation,’ and the third three emphasize ‘sustainability.’ These are nine dots and together they represent BGMEA’s new identity.

So, the nine dots mean:

- People – To forever work for the well-being of the people of Bangladesh and mankind at large.

- Inclusivity – To listen. To be approachable. To involve people across the spectrum and not discriminate.

- Transparency – For accountability and access to information that are central to build a trustworthy, flexible and resilient organization.

- Infrastructure – To build a safe and sustainable future through power plants, green factories, and modern worker friendly workplaces.

- Innovation – For its ongoing contribution to the 4th IR and encouraging automation.

- Circularity – For the conservation of the natural system via an economic shift from a liner to circular system.

- Global network – To be ahead in the world through innovations, pivots and flexible adaptations.

- Brand Bangladesh – To uplift the equity of Brand Bangladesh in the realm of sustainability and to uphold Bangladesh’s values to the world at large.

- Environment – For the respect we have for nature and the dedication to preserving the natural system.

The industry has had some introspection and growing up to do.

Yes, and it is a continuous process. When our new logo was unveiled by Parliament House Speaker Dr. Shirin Sharmin Chowdhury, we presented the BGMEA sustainable strategy, aligned with SDG goals, government targets, and Performance Security Guarantee. We have our upcoming Made in Bangladesh Week 2022, which aims to be a more visible demonstration of our goals, strategies, and adaptations. The weeklong mega event will be portraying the development Bangladesh as a country and the readymade garment industry, as well as what should be our strategic direction aiming the bigger vision. Honorable Prime Minister Sheikh Hasina has kindly consented to inaugurate the event as the Chief Guest.

I recently had a lengthy meeting with our Honorable Prime Minister, where I pointed out that after the incident in 2013, there were stores in many countries that protested by putting up shop signs declaring “We don’t keep anything Made in Bangladesh.” We have worked hard to restore our global image in this regard, and have succeeded to the extent that those very same stores are now fully happy to fill their racks with Bangladeshi products.

As you know, RMG products come with care labels with manufacturing information and care instructions, which are printed in English and French or German, or Chinese, depending on where it is sold. I have sought the blessings of our PM to mandate that care labels of merchandise Made in Bangladesh should have, in addition to English, the text written in Bangla. She agreed.

It is commendable, how quickly the turnaround happened.

In the past decade, our industry has made significant progress in terms of environmental and social sustainability. Other countries are now following our lead. Today our clothing factories are not only safer, but also have become more dynamic, modern, energy-efficient, and environment-friendly. Bangladesh is the home of the highest number of green-certified factories in the world by USGBC. We have now 176 LEED green factories of which 57 are platinum and 105 are gold rated. 41 out of the global top 100 LEED green factories are in Bangladesh. It is also important to mention that around 550 factories are in the pipeline to get their certification. These are state-of-the-art factories, equipped with energy and natural resources, having facilities like rainwater harvesting and daylight saving, and having a healthy and hygienic atmosphere. In social sustainability, Bangladesh has made a tremendous improvement. We have taken several initiatives for protecting occupational health and safety of our workers and workers empowerment. Apart from that, the individual factories of this sector are doing so many CSR activities for the wellbeing of the workers and even for their families. Factories are now following practices like – day care center for workers’ children, healthcare center with full time doctors and nurses, and many other facilities. Ensuring female participation in the higher and mid-level (e.g. CAD operator, supervisor, and Virtual Prototyping machine operator) is one of the most important agenda of our industry. For instance, a total of 90 female garment workers have been given the chance to pursue their graduation at Asian University of Women (AUW) with the assistance from the respective factory owners.

What are your present challenges, you know, with the pandemic and the war in Europe?

Since this is a global issue, no particular country can face the consequences alone. When the world was turning from Covid-19 and getting back from the dire impact created by it, current geo-political issues like the Russia-Ukraine war has further worsened the situation. We expect that with the assistance and support from Bangladesh government, we will be able to overcome this situation too, just like we did in 2008-09.

Currently, one of the major challenges is getting uninterrupted power and gas supply. Also, the price of raw materials has risen significantly which has increased our production cost. Readymade Garments have two raw materials: Cotton for cotton-based fabric, and petroleum for magnet fiber/polyester. We produce only about 1% of the required cotton locally, and import the rest. We don’t manufacture petroleum at all, so securing raw materials to produce at the scale of the second largest global apparel manufacturers is always a challenge, particularly with how things are in the world right now. In addition to this, there are many infrastructural, social, and bureaucratic challenges, which are taking up valuable energy that could be otherwise invested in design, development, and innovation. I’m sure this I don’t need to elaborate on.

Made in Bangladesh Week at a glance

The event aims to showcase impressive stories of the sector, especially its remarkable strides in the areas of workplace safety, environmental sustainability, and workers’ wellbeing.

The Made in Bangladesh Week invites a wide spectrum of industry stakeholders including representatives of governments from home and partner countries, international organizations, employers, private sectors, workers’representatives, civil society, brand representatives, buyers and academics.

The weeklong event will include the following:

➤ 37th IAF World Fashion Convention

➤ 3rd Dhaka Apparel Summit

➤ Bangladesh Apparel Exposition

➤ Bangladesh Denim Expo

➤ Award ceremonies i.e. The Sustainable Leadership Award (TSL), Sustainable Fashion Award, Made in Bangladesh Week, Photography Award, NRB Award

➤ Fashion & Cultural Festival

➤ Photo Exhibition

➤ Green Factory tour

➤ Global Launching of BGMEA Innovation Center and so on.

You have been assuming this amazing leadership role, so as a leader yourself, what do you thing are important qualities?

I have always tried to keep the bridge and balance with our buyers, we also have maintained a good industrial relationship with our workers and laborers, that’s also very important. And we have maintained a very good relationship with the developing partners. We have to keep the balance. Keeping and maintaining the relationships were not easy. But I have made that a priority.

There are concerns and challenges but I am confident that we can bounce back. Before the pandemic, our export was over $34 billion. When I took the responsibility during the pandemic, the exports had dropped to $28 billion, then within one year with all the support of our stakeholders the export increased to $42.6 billion in fiscal year 2021-22 and it’s a record in all terms. This has never happened before. We also have noticed phenomenal growth. I am very happy with the results.

The pandemic was a big challenge, as you mentioned, but we have kept the ball rolling. And we have done it properly. Again, the new challenge is the economic situation because of the Russia and Ukraine war. The inflation has gone up rapidly. To control the inflation, banks and governments all over the world increased the interest rate.

Increasing the interest rate means they are supplying less money in the market. If there’s less money in the market then people are buying less and less. We are working on that, with support from our developing partners, buyers, leaders. So hopefully we will overcome this problem.

What is the best advice you have ever received in life?

The advice I got from my father: “Be good to people.” I have been involved with the business since I was a student. I am happy that whatever advice I got from my father, my parents, I could carry them with me. Because the challenge to sit in the chair of president of BGMEA is not easy. I am getting good support from my colleagues, good friends, etc.

One good thing is that I have always believed in dialogue. When we had an issue with the brands, the governments, etc. I went to the trade union office. The president told me no one from the industry had ever come to his office before. I told him we have an issue, we believe in dialogue, so we had a dialogue. This is how we are branding Bangladesh, we are branding the RMG sector, so I have visited all the places to do these things.

Photographer: Farabi Tamal

Fashion Direction & Styling: Mahmudul Hasan Mukul

Make-up & Hair: Md. Shohag

Assist. Stylist: Morshed Ranan

Location: BGMEA Complex

- tarin fatema

- tarin fatema

- tarin fatema

- tarin fatema

- tarin fatema

- tarin fatema

- tarin fatema

- tarin fatema

- tarin fatema

- tarin fatema

- tarin fatema

- tarin fatema